semi-automatic pvc corner welding machine for refrigerator gasket

| Product Name | Automatic refrigerator door gasket seal welding machine |

| Brand Name | ASPECT |

| Gross Weight | 550kg |

| Size | 180cm×128cm×124cm |

| Welding Area | 40mm×100mm |

| Longitudinal mold opening route | 100mm |

| Horizontal mold opening route | 50mm |

| Drive form | Gas driven |

| Control system | Omron PLC programmable circuit control system |

| Application | Use for soldering refrigerator / fridge gasket rubber seal corner to 90 degree |

| Function | Welding soft PVC rubber profile corner |

| MOQ | 1 set |

| Material Origin | China |

| Quality Guarantee Period | 1 year |

| Mold Service | Custom welding mold base on customer drawing or sample, test mold welding affect |

| Other Service | OEM &OEM, Customized Specification, One to One Communication |

| Voltage / Power / Frequency | 380V (Three-phase current) / 2.2Kw / 50-60HZ |

Features

1) This machine adopts advanced Omron PLC control system, famous-brand cylinder, and imported electrical parts to keep machine high-automatic, high-efficient, easy operating and long-service time.

2) This machine can weld 2 gasket corners every time, after welding, it cleans (trims) extra material automatically to make it nice, firm and beautiful surface of welding corner.

3) The welding process is: heating -vacuum adsorption - welding -inner cooling -outer cooling -pops up automatically.

4) the welding mould goes with vacuum system, and inner cooling system, which can make the surface of gasket corner smooth and the inner cooling system can avoid gasket zones sticking together.

5) Photoelectrical protection system is used to protect hands from being pinched during operation.

6) Welding speed is 11~14 second/ two corners, the output can reach 600~650 sets every 10 hours.

7) This machine has earned CE certificate and been exported to different countries all over the world.

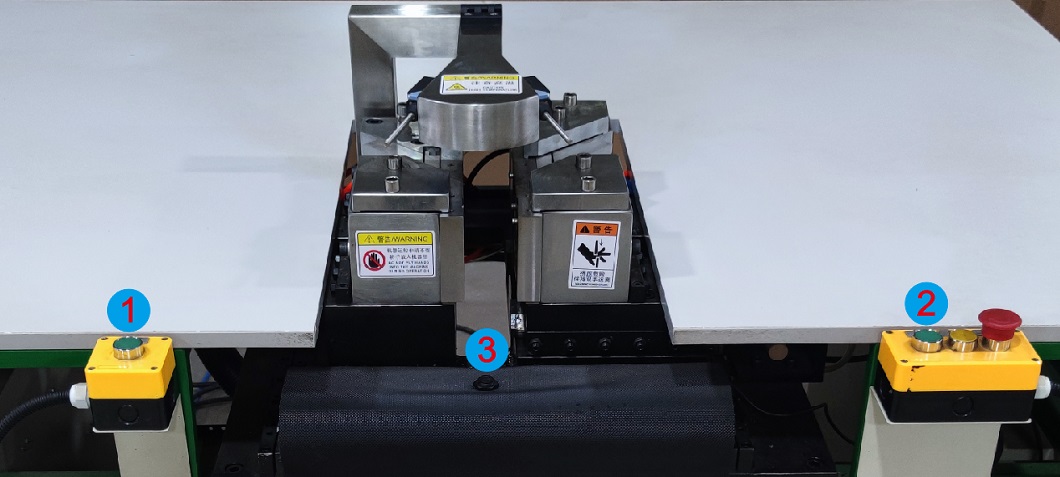

Safety

Double switch button (Starts by pressing the button ①② at the same time only), ③ photoelectric protector (the mold will not merge when any object is sensed there)

|

High efficiency Two door seal corners can be welded at the same time, and the extra parts around the corner will be automatically cleaned after welding and the door seal will be ejected.

|

|

Energy saving The heating part adopts 3 spiral heating tubes embedded in the middle of the stainless steel cylinder, which can effectively improve the heat storage capacity and reduce the heat loss.

|

|

|

Control system Omron PLC programmable circuit control system, saving electronic components, easy to troubleshoot and repair.

|

|

Adjusting system Heating temperature, heating time, cooling time, mold merging time can all be adjusted by mechanical knob.

|

|

|

Exhaust system The top design is a ventilation system that can absorb and collect welding exhaust gas and discharge it outdoors.

|

|

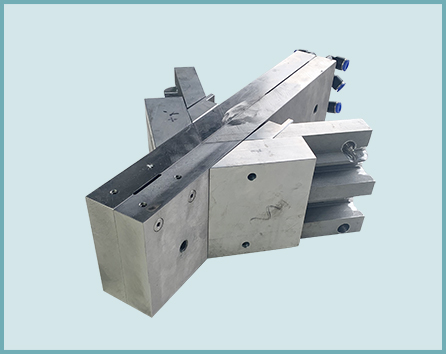

Precise mold The mold is composed of 10 parts, processed by line cutting, thread tapping, fine carving, manual grinding and other processes.

|

|

|

The welding surface is flat and firm The built-in vacuum adsorption makes the door seal and the mold connected tightly. The sharp carving blade automatically cuts the remaining material off. The gas passes through the welded joints at high speed to cool them down quickly and make it unbreakable.

|

We are manufacturer of refrigerator gasket too

Alibaba refrigerator gasket TOP supplier

Please Click below image if you need order refrigerator gasket in Alibaba

Our customers

Related Products

| Refrigerator gasket | Mini refrigerator gasket welder | Refrigerator gasket 45 degree corner cutting machine |

|

|

|

Contact Us